SUMICO

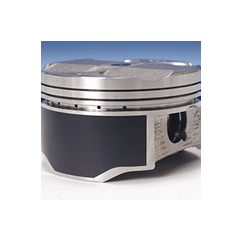

Dry lubricating films containing solid lubricants

Dry film lubricants formulated with solid lubricants, such as molybdenum disulfide(MoS2), PTFE and graphite, and binders. Applied like a coating, they form a...